What is Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) as a new type of non-toxic environmental protection plasticizer, it is widely used in polymer products such as plastic and rubber, and has been recognized by most countries. ATBC has the advantages of environmental protection, non-toxic and is used in medicine, food and other fields. It also conforms with environmental standards of EU, USA and other developed countries.

What are the chemical properties of Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) is a clear, odorless, practically colorless, oily liquid. It has a very faint, sweet, herbaceous odor. At high levels (e.g., 1000 ppm emulsion in water), it has a mild, fruity, nondescript flavor. Its water solubility is less than 0.002 g/100 mL, but it is soluble in organic solvents.

What is the solubility of Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) is not miscible with water, miscible with ethanol (96 per cent) and with methylene chloride.

What is Acetyl Tributyl Citrate (ATBC) used for?

Acetyl Tributyl Citrate (ATBC) is colorless, tasteless, non-toxic and degradable, it is soluble in a variety of organic solvents but not soluble in water and does not hydrolyze, especially in boiling water for 6 h, it is difficult to hydrolyze, and nitro fiber, ethyl fiber, chlorinated rubber, slightly soluble with acetate fiber, Can be used for heat and light resistant food packaging in dairy products, beverage bottles, bottle food sealing ring and medical machinery, toys, non-toxic PVC film, sheet, fiber coating, polyvinyl acetate, polyvinyl alcohol acetyl. Aldehydes, polystyrene, such as plasticizer, poly vinylidene chloride stabilizer.

Pharmaceutical Applications:

Acetyl Tributyl Citrate (ATBC) is used to plasticize polymers in formulated pharmaceutical coatings, including capsules, tablets, beads, and granules for taste masking, immediate release, sustained-release and enteric formulations.

Other Applications:

Non-toxic plasticizer for food packaging materials such as dairy products, beverages, food, etc.

F.D.A approved for use in children's toys.

Used as plasticizer of PVC, cellulosic resin and synthetic rubber.

Used in PVC prilling, medical products, films, plates and printing ink.

Used as stabilizer of PVC.

What is the production method of Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) is prepared by the esterification of citric acid with butanol followed by acylation with acetic anhydride.

What is the incompatibility of Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) is incompatible with strong alkalis and oxidizing materials.

What is the storage condition for Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) should be stored in a well-closed container in a cool, dry location at temperatures not exceeding 38℃. When stored in accordance with these conditions, acetyltributyl citrate is a stable product.

What are the first aid measures after contact with Acetyl Tributyl Citrate (ATBC)?

If inhaled

If breathed in, move person into fresh air. If not breathing, give artificial respiration.

In case of skin contact

Wash off with soap and plenty of water.

In case of eye contact

Rinse thoroughly with plenty of water for at least 15 minutes.

If swallowed

Never give anything by mouth to an unconscious person. Rinse mouth with water.

What are the advantages of Acetyl Tributyl Citrate (ATBC)?

Acetyl Tributyl Citrate (ATBC) has non-toxic, odorless, heat resistance, cold resistance, water resistance and other comprehensive properties, is an ideal plasticizer for food packaging and medical equipment. It has been certified non-toxic by the Food and Drug Administration (FDA). After PVC is plasticized by ATBC, it has the advantages of good low temperature warping, heat stability and no discoloration. Under the condition that ATBC and DOP are in phase. The plasticizing efficiency of ATBC is slightly higher than that of DOP. The main mechanical properties are close to DOP.

What are the key driving factors for the Acetyl Tributyl Citrate (ATBC) Market?

The increasing use of Acetyl Tributyl Citrate (ATBC) In Children Toys, Daily Chemical and Food Package, Medical Devices and Package and other industries is driving the growth of the Acetyl Tributyl Citrate (ATBC) market across the globe.

How is Acetyl Tributyl Citrate (ATBC) exported?

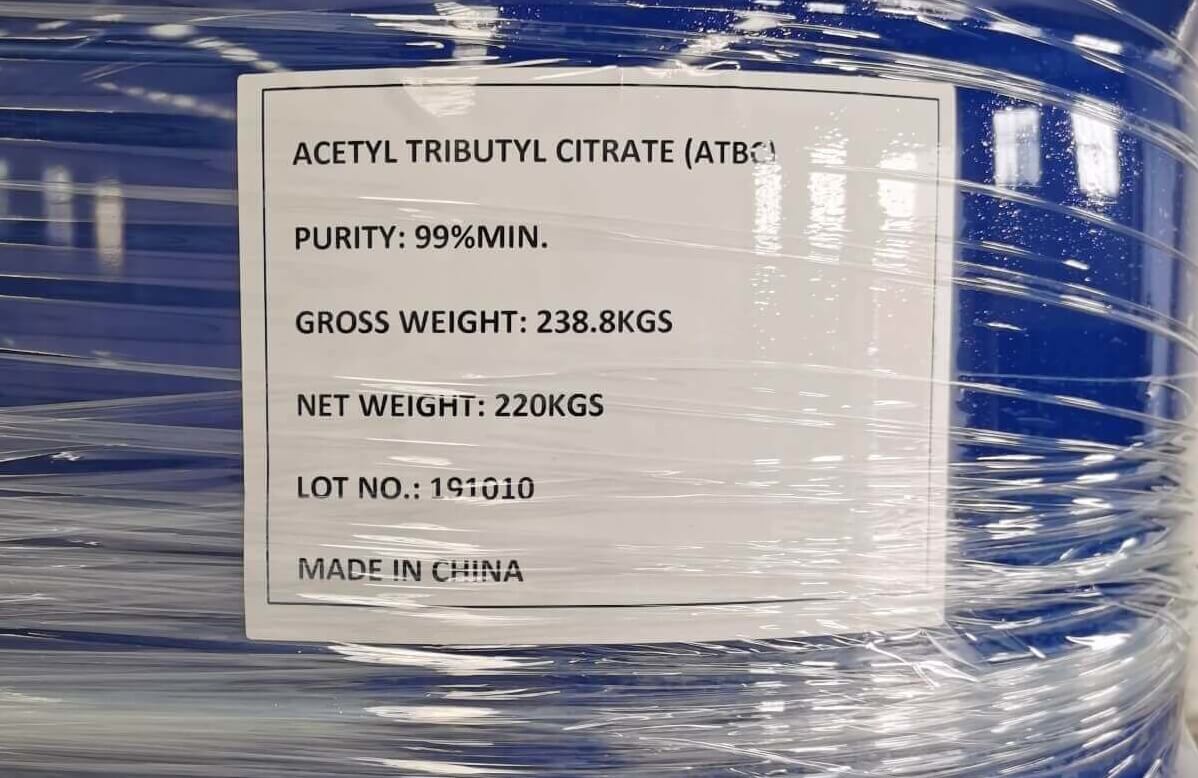

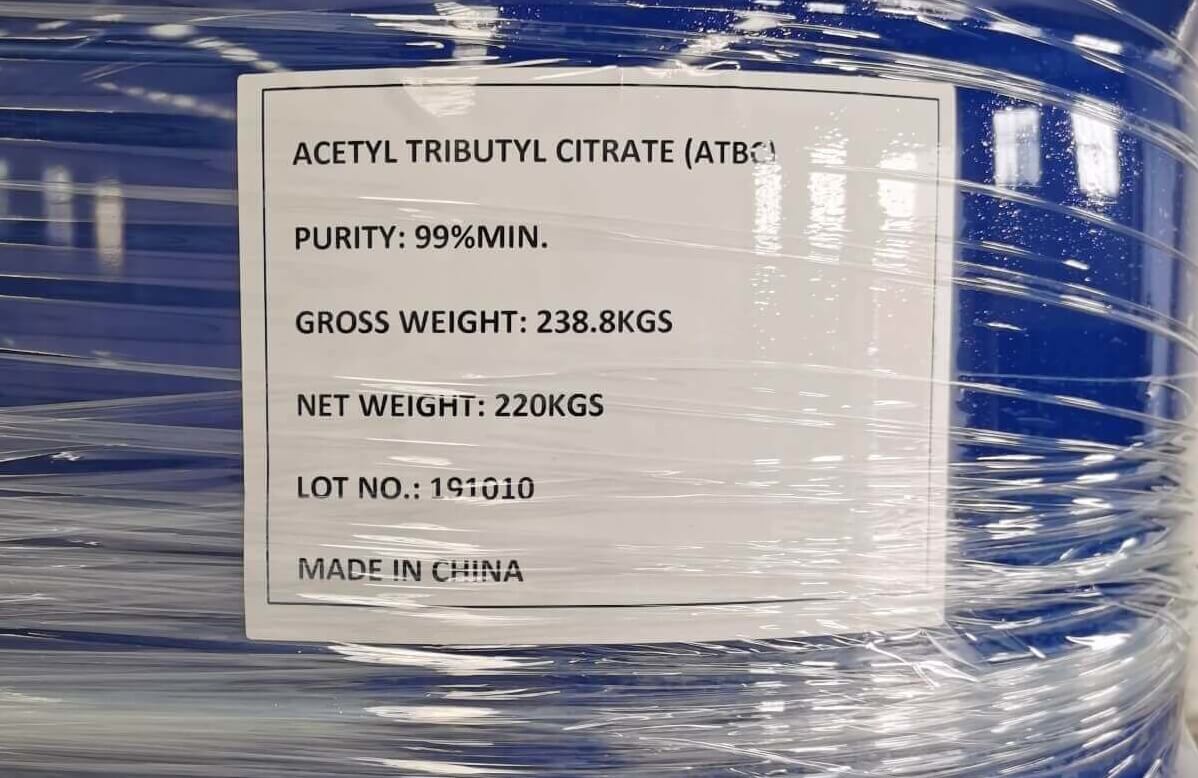

For large orders:

LCL or FCL from Port of Shanghai, China. 220kg Iron drum or 1000kg IBC Tank.

For samples:

By Fedex or DHL

What is the application prospect of Acetyl Tributyl Citrate (ATBC)?

As a new type of non-toxic, tasteless and degradable plasticizer, Acetyl Tributyl Citrate (ATBC) can completely replace toxic phthalate. It is widely used in rubber, plastic household appliances, kitchen and bathroom, daily necessities, health care, toys, sporting goods, food, agriculture, building materials, textile fiber, information communication, defense equipment, aerospace and other fields. In recent years, the output of citric acid manufacturers has increased year by year, and more market supply, the price of non-toxic citric acid ester plasticizer is moderate, with broad market prospects.

Children's toys:

With the continuous discovery of DOP toxicity data, more and more fields are prohibited to use DOP, and Acetyl Tributyl Citrate (ATBC) is non-toxic, tasteless, good in transparency, low in water extraction rate, and has excellent processing performance of plasticized plastic products. , especially suitable for use as the main plasticizer for children's toys.

Meat product packaging:

Acetyl Tributyl Citrate (ATBC) is non-toxic and can be used as meat product packaging material, while DOP cannot be used in the field of high-fat food packaging. Moreover, it is odorless and will not cause food odor. The plasticized plastic products are transparent and have good printing performance.

Medical products:

Acetyl Tributyl Citrate (ATBC) is non-toxic, low water extraction rate, no potential harm to human body, and its plasticized medical products have good high and low temperature resistance.

As an excellent plasticizer, Acetyl Tributyl Citrate (ATBC) not only meets the requirements of non-toxic plasticizer, but also can be used in general plastic products. Cellulosic film plasticized with ATBC has low volatility loss and strong adhesion to metal compared with cellulosic film containing DBP.

Where to buy Acetyl Tributyl Citrate (ATBC)?

As a professional supplier of Acetyl Tributyl Citrate (ATBC), Ao Zun serve the global enterprise customers. If you need a quotation or sample, please feel free to contact us via e-mail mandy@czqidi.com or send a message on WhatsApp at +86-18452425579.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Eesti keel

සිංහල

latviešu

Български

Hausa

íslenska

Kurdî

Lietuvių

isiZulu